Compost Group

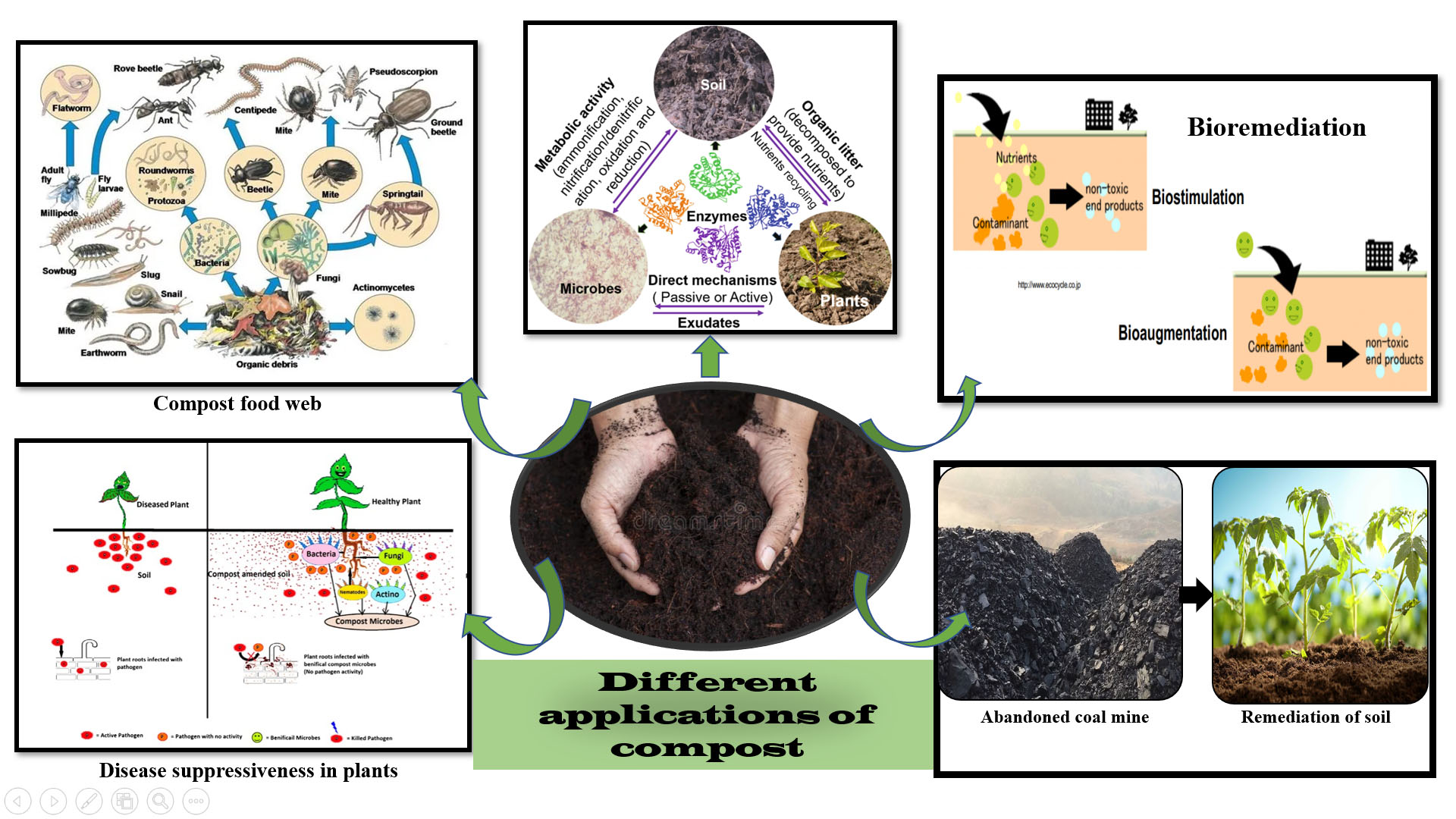

The Compost team has tried to address a range of real-time problem statements both currently and in the past. The goal of our research team has been to leverage biological transformation activity, specifically composting and vermicomposting, to mitigate unmanageable lignocellulosic waste into nutrient-rich end products. The group has worked on diverse forms of organic wastes such as vegetable wastes, pulp, and paper mill waste, sludge, different terrestrial and aquatic weeds, etc. which are a menace to the ecosystem. Our expertise encompasses a range of composting processes, including pile composting, rotary drum composting, vermicomposting, and the most recent approach of rotary drum composting followed by vermicomposting (RVC). The above-mentioned composting methods have been used to control weeds. The current research focuses on several areas, namely the production of biofortified compost, the study of invertebrate diversity during composting, the restoration of pesticide-contaminated and coal mining areas using compost and vermicompost, as well as the degradation of allelochemicals during composting adopting microbes.

Reactors

A 5000-litre RDC unit and a 3000-litre stack vermicomposting unit were established to study the large-scale effect of the process. A 7 HP motor was installed to assist the drum’s rotating motion. A 2 HP air blower was utilized to aerate the feed biomass. The reactor was 3.8 meters long. The reactor was installed on a cast iron frame and rollers for convenience of operation

A novel technology to minimize biodegradation time, yielding vermicompost in 27 days for urban waste management and reduces the waste volume by 71% and producing a nutrient-rich soil conditioner with 4.2% total nitrogen.

Compared to other waste biodegradation techniques that require 2-3 months, Rotary Drum Composting (RDC) can convert diverse organic feedstocks into nutrient-dense compost within just 20 days and significantly reduce the municipal waste volume by 60-70%. However, the limitation of RDC is inferior compost quality. Vermicomposting is a superior biodegradation process that traditionally requires a minimum of 60 days, making the process less adaptable for urban municipal corporations.

A rotary drum composter with a capacity of 550 L was utilized to study the batch-scale effect of the process. The composter had dimensions of 1m in length, 0.8m in diameter, and a thickness of 4mm. The composter was affixed to a metallic chassis featuring four resilient rims and was actively rotated via its handle. To ensure uniform mixing and aeration within the composter, longitudinal installation of 40x40 mm angles was implemented.