Prof. Kaustubha Mohanty

Professor

Key Research Areas :Biofuels, Biomass pyrolysis, Biological wastewater treatment, Heterogeneous catalysis, Microalgae biorefinery, Membrane based separations, Ionic liquid based separations, Waste management.

- Phone No: +91 361 258 2267

- Email: kmohanty@iitg.ac.in

- Room No: 0202

Google Scholar | Scholar GPS Profile | Scopus Profile

| S. No | Post Held | Organization | Experience |

| 1. | Professor (HAG) | IIT Guwahati | Since 15 September 2022 |

| 2. | Professor | IIT Guwahati | Since 15 September 2015 |

| 3. | Associate Professor | IIT Guwahati | 15th February 2011 to 14 September 2015 |

| 4. | Assistant Professor | IIT Guwahati | 16th January 2007 to 14th February 2011 |

| 5. | Sessional Lecturer | McMaster University, Canada | 2006 |

| 6. | Postdoctoral Fellow | McMaster University, Canada | 2006 |

| 7. | Postdoctoral Fellow | Ben-Gurion University, Israel | 2005 |

| Data Regarding Research |

- Total no. of papers in Referred Journals: 250

- Books (co-authored/co-edited): 08

- Book Chapters: 31

- Ph.D Supervision (Completed+Thesis Submitted): 30

- Ph.D Supervision (Undergoing): 15

- M.Tech/MS Supervision (Completed): 42

- M.Tech/MS Supervision (Undergoing): 02

- B.Tech Supervision (Completed): 37

- B.Tech Supervision (Undergoing): 02

- h-index*: 63

- i10-index*: 193

- Total Citations received*: 13174

(*Source: Google Scholar, as on 03-02-2026)

Click here for Google Scholar Citation

Research

Biological Wastewater Treatment

Our work is more focused on two most abundantly found pollutants, one is phenol and the other is chromium in its hexavalent from. Biosorption involves uptake of pollutants by both live and dead biomass whereas biodegradation is a metabolically oriented process by live microorganisms which can be aerobic or anaerobic. The most important aspect of biological wastewater treatment is the selection of a suitable biomass. We have developed and characterized various biosorbents from fish scale, Hydrilla weed, nutshell of gulmohur tree etc. which were successfully utilized for biosorption of Cr(VI) from wastewater. Similarly for the treatment of phenol, a mixed microbial culture was isolated from wastewater of a local refinery and tested. Complete degradation of phenol was achieved up to a concentration of 1000 mg L-1. Treatment of Cr(VI) rich wastewater using P. chrysosporium, a white rot fungi and Halomonas sp., a bacteria was carried out in our laboratory successfully. It was evident from this study that the free cells of Halomonas sp. and its CFE (Cell free extracts) can be used for the reduction of lower concentration Cr(VI) in an ecofriendly manner. One bacterial strain isolated from soil samples contaminated with tannery wastewater and identified as Bacillus cereus was used for the bioreduction of Cr(VI). We are working on the mechanism of heavy metal detoxification by fungus which is very ill understood. Work on enzymatic detoxification of heavy metals is also planned.

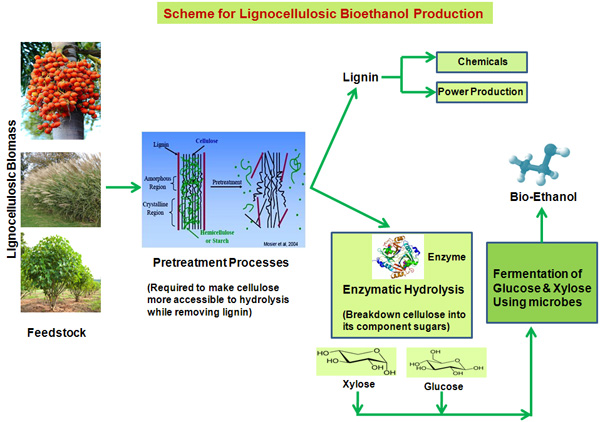

Biofuels

Developing country like India needs advanced production and processing technology to secure its energy needs. Hydrogen and ethanol derived from lignocellulosic biomass are promising biofuels and of great potential to become alternatives to fossil fuels. Pretreated lignocellulosic biomass results in two main streams: one rich in cellulose (hexose: glucose) and the other rich in hemicellulose (pentose: xylose and arabinose). By choosing appropriate biocatalyst, cellulosic part can be effectively converted to ethanol and the hemicellulosic part can be utilized to produce hydrogen in the same reactor. However, the metabolic pathway for hydrogen and ethanol production often conflicts with each other from the perspective of metabolic electron transfer thereby limiting the production to a single biofuel (either hydrogen or ethanol). We are working on the methods to optimize the metabolic pathway to produce both hydrogen and ethanol simultaneously. Pretreatment of lignocellulosic biomass to produce carbohydrate is an indispensible part towards biofuels production. North-East India is blessed with a huge biomass reserve and we have collected various waste and unutilized biomasses such as Areca nut (Areca catechu) husk, Moz (Albizia lucida), Bon bogori (Ziziphus rugosus), arjun nut (nut of Tamarindus indica), rice husk etc. Work on complete characterization of these biomasses by several pretreatment techniques such as dilute acid pretreatment, ultrasound assisted lime pretreatment and hot water treatment at subcritical pressure are done with encouraging results. Currently we are working on ionic liquid based biomass dissolution. We are also working on biomass fractionation using sub-critical and super-critical water.

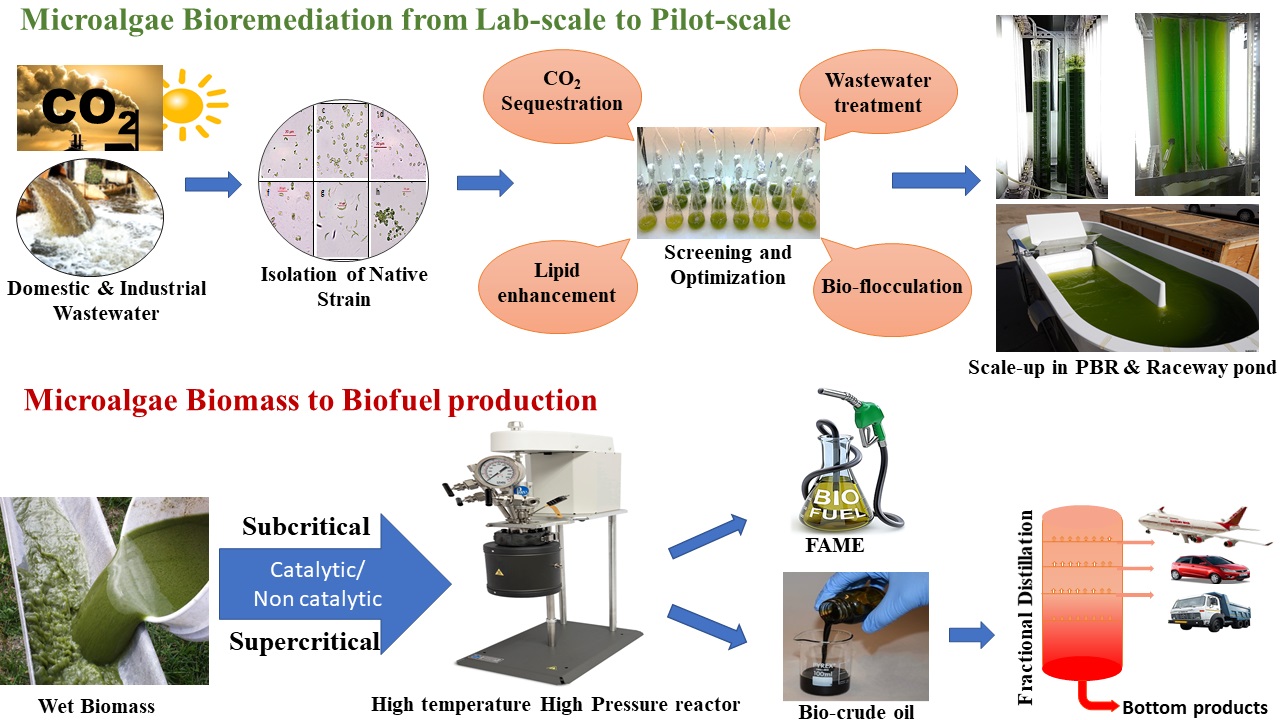

Microalgae based biofuels and other value added chemicals

Microalgae are widely considered as energy factories and potential feedstock to produce 3rd generation biofuel. However, selection of potential strains, low-cost growth nutrients, efficient harvesting techniques, and energy efficient biomass to biofuel conversion are the major bottlenecks that need to be addressed to make microalgae biorefinery sustainable. To address the gaps our research group is focusing on various aspects of microalgae biorefinery system. These include CO2 sequestration, wastewater as an alternate to growth nutrients, photoheterotrophic studies using organic wastes, catalytic and non-catalytic transesterification, and biocrude oil production through hydrothermal liquefaction (HTL).

To achieve significant results, our research group has isolated more than 20 microalga strains among which 13 potential strains were genetically identified and sequences were submitted to NCBI. Among these, S. obliquus SA1 (KC733762) exhibited tolerance to high concentrations of CO2 (13.8 ± 1.5%) and temperature (40 ℃). In another study, sewage wastewater was used as an inexpensive alternative to freshwater based culture media for growth of C. thermophila (MF179624) resulting in biomass yield of 2.59 g L-1. Besides lab-scale studies, process development was carried out in a 20 L indoor photobioreactor (PBR) which enhanced biomass yield significantly through batch, fed-batch and semi-continuous mode of operation. In a recent study, fruit peels collected from local juice vendors were hydrolyzed and turned into an optimal microalgae growth nutrient for photoheterotrophic study. The study also explored sustainability and scalability of the process. In another study, effect of stress on lipid productivity was investigated. Additionally, pilot-scale studies on an outdoor photobioreactor of 100 L and raceway ponds of 500 L and 2000 L is under progress in collaboration with Prof. D. Das (IIT Kharagpur) with financial support from IMPRINT I (MHRD), Govt. of India. The project aims to generate high-value microalgae biomass feedstock, HTL, and fractional distillation of biocrude oil using ASTM standards.

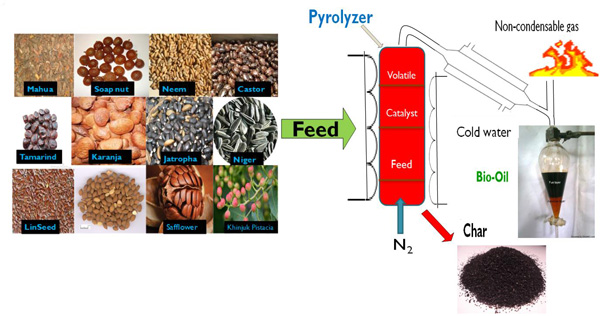

Biomass Pyrolysis

Pyrolysis is a common method to convert organic rich biomass into fuel. It is an irreversible process during which phase change occurs along with a change in composition. During pyrolysis, the internal structure of the biomass is thermally decomposed at elevated temperatures with or without the supply of oxygen. Biomass pyrolysis usually results in three different types of products viz. solid, liquid and gas, all of them having high economic value. The solid product is carbon-rich, usually known as bio-char and can be used as a solid fuel or bio-adsorbent. Higher volatility of the char makes it very flammable as similar to coal. It can be stored in open atmosphere for a long period. The non-condensable volatiles which contains mainly CO, CO2, CH4 and H2 (syngas) formed due to the primary and secondary reaction and can be used as gaseous fuel. The liquid product obtained from the condensable volatiles is rich in organic compounds and known as pyrolytic oil (or bio-oil). This is the most important product of pyrolysis. The pyrolytic oil can be used with or without up-gradation as an alternative fuel for diesel engine which has closer physical and chemical properties to that of diesel. The characteristic and composition of the pyrolytic oil is a function of feed types, composition (hemicelluloses, cellulose, lignin and extractive) and the initial moisture content. Higher percent of cellulose and hemicelluloses are responsible for formation of more liquid, while lignin is responsible for production of more char with less amount of liquid. The presence of extractives in feed is responsible for high organic liquid yield. With an aim to have more yield of bio-oil, we have chosen various non-edible oil seeds such as Mahua, Karanja and Niger seeds as feedstock for pyrolysis. The results of our study confirmed that the total pyrolytic liquid is a mixture of both organic and inorganic liquid. The organic liquid is considered as oil and rich in hydrocarbon, aromatics, esters, acids, phenols, ketones and aldehydes whereas the inorganic liquid is mixture of water and water soluble chemicals. Detail characterization of the fuel properties of the bio-oil is being carried out. Catalytic pyrolysis in the presence of various catalysts are undertaken to improve the fuel properties of the bio-oil. More work is going on to determine the optimized condition for maximizing the yield and quality of bio-oil oil from non-edible oil seeds followed by various up-gradation techniques.

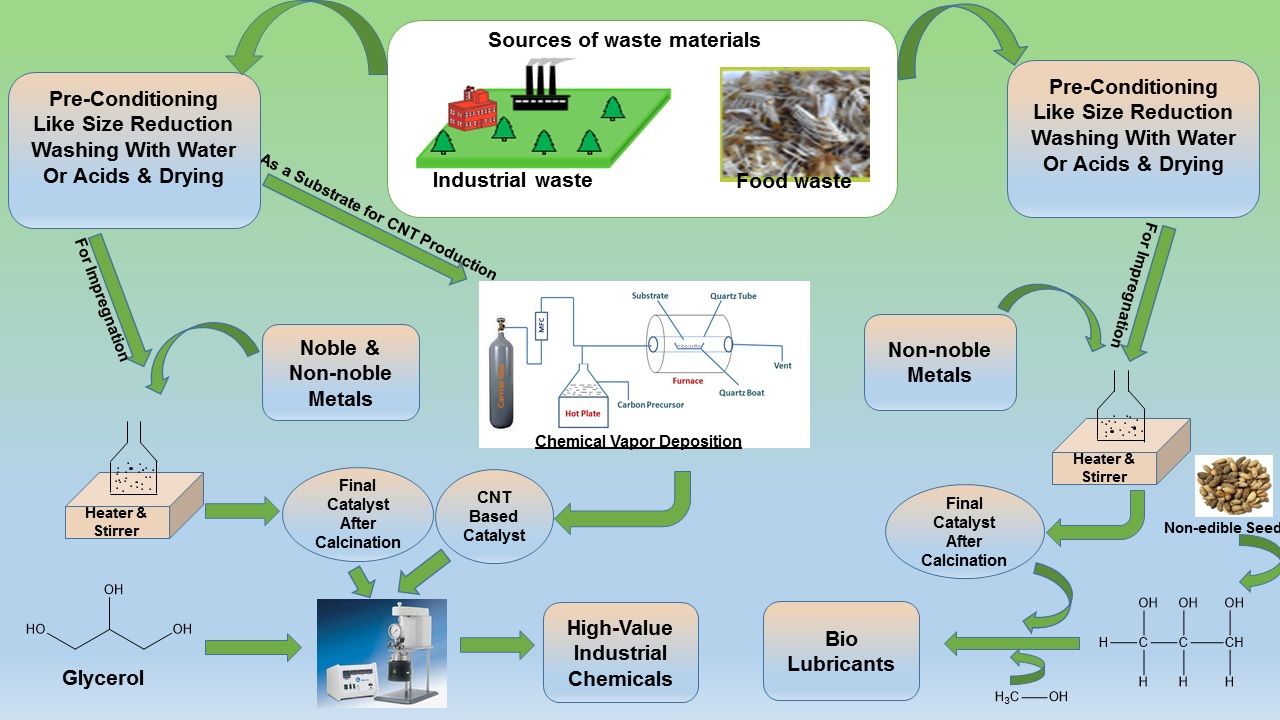

Heterogeneous Catalysis

Catalyst plays a prominent role in various industries and many energy-intensive processes rely on heterogeneous catalysts. Although there has been lots of development, however, the cost associated with the preparation of highly efficient catalysts effects directly the overall economy of the process. Therefore, the focus is now developing cost-effective catalysts from different low-cost materials that can reduce the energy consumption and creates less environmental impact. In our laboratory at IIT Guwahati, we focus on developing heterogeneous catalysts from wastes originating from different sources like industries, bio-waste and food wastes etc. Different High performance technology like XRD, XPS, FTIR, BET, FESEM, FETEM, EDX, TGA-DSC, RAMAN and chemisorption are used for identifying the physical and chemical characteristics of the prepared catalysts. Our recent application of the prepared catalysts are based on the synthesis of bio-lubricants, bio-diesel and other highly demanded industrial chemicals from renewable sources. Highly efficient custom designed experimental setups are used for performing these chemical processes in our laboratory. Our recent application of the catalyst developed from alumina and magnesium doped waste fish bone has produced close to 98% and 96% conversion of Neem oil at 90 oC for the production of bio-lubricant through transesterification process. The process has been optimized by using Response Surface Methodology (RSM) and detail kinetic and thermodynamic study was also carried out. Similarly, catalysts derived from waste of aluminum industries was applied for the synthesis of transesterification of glycerol (waste from bio-diesel industries). The results obtained from the application of different prepared catalysts suggests that these catalysts have the potential for commercialization in future for the above applications and can add significantly to the economy of the process at the same time creating pathway for utilization of these waste materials.

Instrument Facilities

| Experimental (Batch Mode Reaction) Facilities | ||

|

High-Pressure (5000 psi) High-Temperature (500 oC) Batch Reactor |

Low-Pressure (73) Low-Temperature (150 oC) Batch Reactor |

Fermenter Autoclave |

| Algal Culture Facilities | ||

|

Algal Culture |

Algal Culture |

Algal Culture |

|

Algal Culture |

KMC4 Biomass & LEMB |

Harvested Biomass Slurry |

| Analytical Instruments Facilities | ||

|

Gas Chromatography (Perkin-Elmer) |

Thermogravimetric Analyzer (Perkin-Elmer) |

V-VIS Spectrophotometer (Thermo-Fisher) |

|

Spectrophotometer & Quantum Meter |

pH Meter & DO Meter |

COD Estimator |

|

|

Rotary Evaporator (Buchi) |

|

| Others | ||

|

Incubator, Open & Vortex Shaker |

Fume Hood |

Autoclave, Heating Bath & Photoincubator Shaker |

|

Large & Micro Centrifuge |

Vacuum Oven, Muffle Furnace & Microwave Oven |

Compressor & Peristatic pump |