In our BioPAT lab facility, we do bioprocess development taking account of all critical process key parameters into process design. Measurement, monitoring, and control (M3C) of key parameters is achieved by integration of real-time process analytics (e.g., calorimetry, dielectric spectroscopy, exhaust gas analysis, software sensors) with a bioprocess system. Our range of products of interest include therapeutic proteins (cancer therapy), biopolymers, and platform chemicals. BioPAT is an emerging research area and deserves potential industrial application involving upscaling of a bioprocess system in accordance with FDA norms. Indian biotech sector is now embracing the FDA's PAT initiative in bioprocess systems to ensure consistent quality in final products.

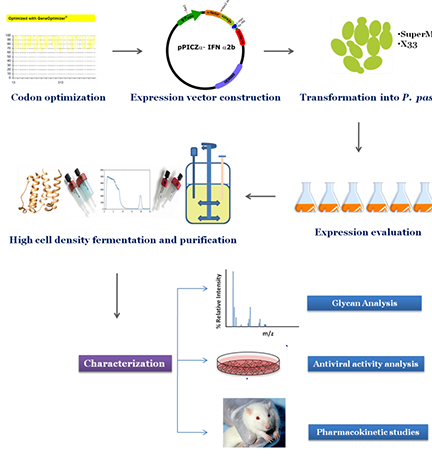

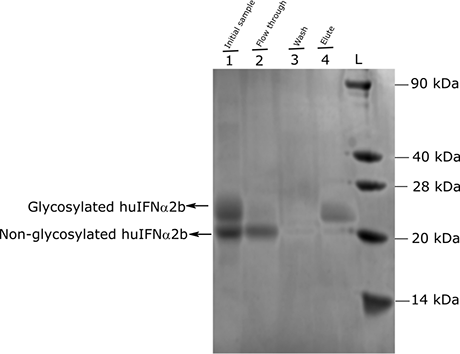

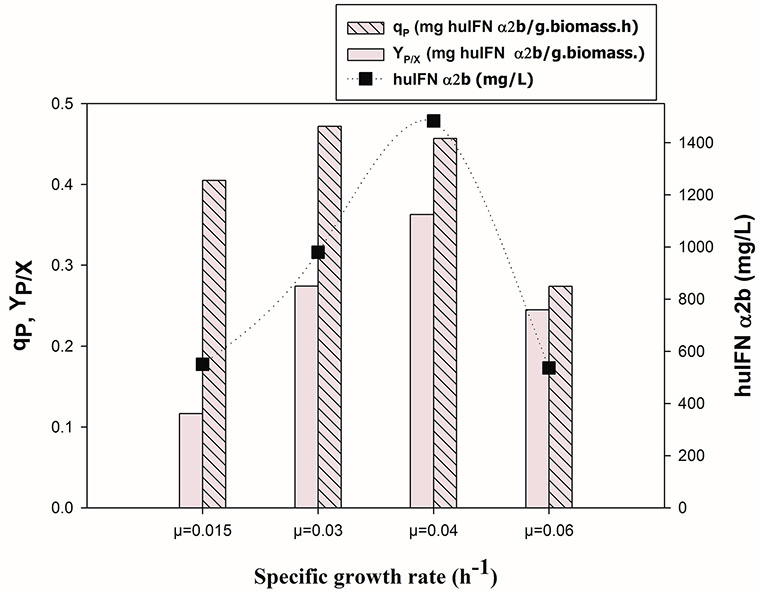

Human interferon alpha 2b (huIFNα2b) is an intronless sequence that encodes a polypeptide of 165 amino acids. It can trigger multiple responses that could be antiviral, antibacterial, antiproliferative, or even immunomodulatory. Therefore, huIFNα2b either on its own or in combination with other interferons is being extensively used in prophylaxis of type B and C hepatitis, several cancers such as melanoma, AIDS-related Kaposi sarcoma, chronic myeloid lymphoma, and angioblastoma. Our group successfully engineered a recombinant glycosylated huIFNα2b-producing strain. High cell density cultivation of glycoengineered Pichia pastoris embraced by the PAT framework produced a significant improvement in huIFNα2b titer (1.4 g/L) by application of a robust control strategy. Currently, our research is directed towards developing control strategies to maintain tight control over specific growth rates to ensure consistent product quality.

Cloning, expression, purification, and characterization of recombinant human interferon alpha 2b in Pichia pastoris

SDS-PAGE of fractions collected during Concanavalin A purification of glycosylated huIFNα2b

Influence of different specific growth rates (μsp) on huIFNα2b titer and protein yield coefficient

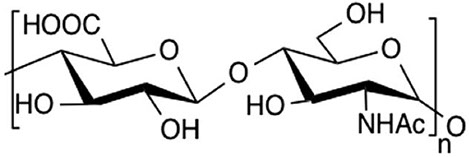

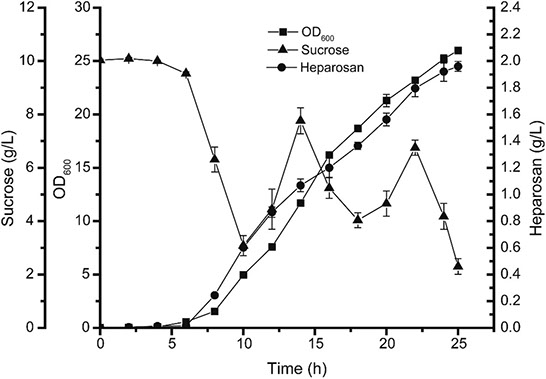

Heparosan is an anionic, un-sulfated precursor of heparin. It is composed of repeating disaccharide units of D-glucuronic acid and N-acetylglucosamine. Traditionally, heparin was derived from animals but caused serious adverse reactions leading to hypotension and the death of the patients. Chemoenzymatic synthesis of heparin emerged as an attractive alternative that requires heparosan as a starting molecule. Although significant yield was achieved in E. coli K5, it suffered severe disadvantages of causation of urinary infection in humans, secretion of exo and endotoxins which hindered its use. The global heparosan market is expected to increase because of its tremendous demand in the biopharmaceutical industry. Using metabolic engineering approaches, we successfully expressed heparosan in Bacillus megaterium. Currently, novel bioprocess strategies are aimed in order to enhance its production.

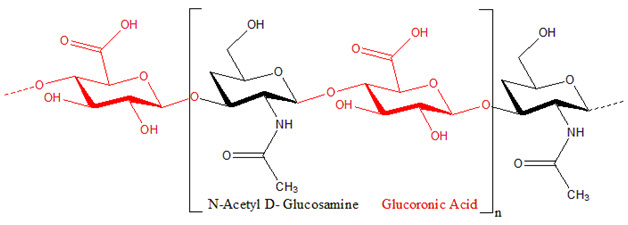

Molecular structure of heparosan composed of repeating disaccharide units of GlcA and GlcNAc linked by β (1→4) and α (1→4) glycosidic bonds

Lactic acid bacteria (LAB) is a viable option for heparosan production. It has grabbed much attention because of their reputation for being “GRAS”. GRAS organisms are commonly preferred to produce food grade, pharmaceutical grade products owing to its safety and availability of wide range of genetic manipulation tools. Presently, we are targeting LAB for heparosan production using metabolic engineering approach.

Heparosan production by recombinant B. megaterium in a lab scale bioreactor. The graph illustrates the time-dependent changes in sucrose concentration, OD600, and heparosan production.

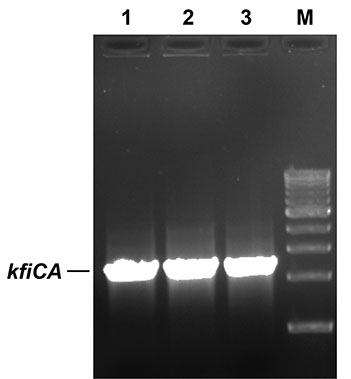

PCR confirmation of E. coli kfiC and kfiA genes in B. megaterium. The gel bands validate the successful gene incorporation.

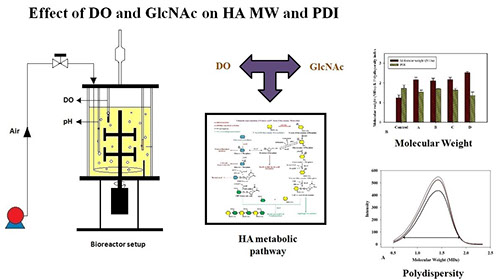

Hyaluronic Acid (HA) is a linear, non-sulphated, anionic muco-heteropolysaccharide made of repetitive monomer units of UDP N-Acetyl glucosamine (UDP-GlcNAc) and UDP D-Glucuronic acid (UDP-GlcUA) alternately. The colossal significance of HA finds its application in the areas of medicine and cosmetics, such as drug delivery, osteoarthritis and ophthalmology surgery, wound healing, tissue engineering, moisturizer, dermal filler, etc. The molecular weight of HA is a critical quality attribute that determines its usage in various end applications and demands attention to achieve the consistent quality of the final product.

Molecular structure of hyaluronic acid.

The complexity in the HA production process has more to be dealt with the process engineering maneuvers than the genetic engineering approaches. Our lab designed different process strategies and successfully utilized PAT tools on monitoring and control of various critical process parameters (CPPs) influencing HA titer and molecular weight. Application of recombinant GRAS organisms as host is in progress to achieve high molecular HA production.

Figure 2: Effect of dissolved oxygen and GlcNAc on HA molecular weight and polydispersity index.

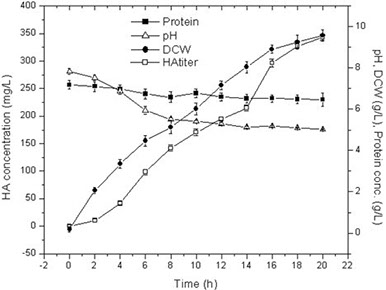

Dynamic profiles of DCW (g/L), pH, total protein concentration (g/L), and hyaluronic acid (mg/L) during batch cultivation of S. thermophilus under global optimal conditions.

HA is commercially produced by extraction from rooster comb and by fermentation of natural and potentially pathogenic microbial producer Streptococcus zooepidemicus which is known to cause infections in the respiratory tract. Presently, our group is actively involved in metabolic engineering of GRAS organism as a host to achieve high molecular weight and more disperse HA synthesis.

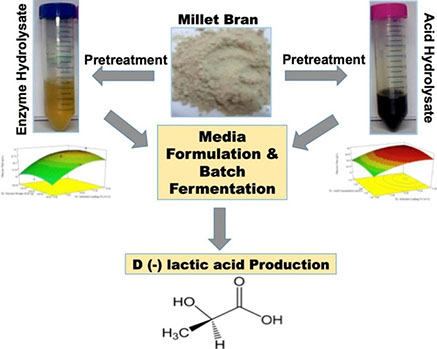

D (–) Lactic Acid (DLA) is a versatile organic acid molecule, extensively employed in the production of thermostable biodegradable polymer, polylactic acid (PLA). Optically pure DLA is a prerequisite for the production of PLA with improved mechanical and thermal properties, expanding its scope in food packaging applications. Microbial fermentation processes offer an attractive techno-economic strategy to produce optically pure DLA compared to racemic mixtures yielding expensive chemical synthesis. However, the choice of raw feedstock and its preprocessing requirements for microbial fermentation decides the fate of the final product cost.

Our team is actively pursuing designed biomass approach (DBA) to elucidate the right choice of raw feedstocks, preprocessing strategies, and elite strain targeting to enhance DLA titer and its productivity. The global demand for LA derivatives requires feedstocks that are economically viable and environmentally sustainable. Exploration of low-cost feedstocks and the right choice of process engineering strategies could markedly reduce the DLA production cost. We examined Kodo Millet Bran Residue (KMBR) and agroforestry/industry biomass as an alternative substrate.

Schematic representation of enzyme and acid hydrolysis of kodo millet (Paspalum scrobiculatum) bran residue for DLA production.

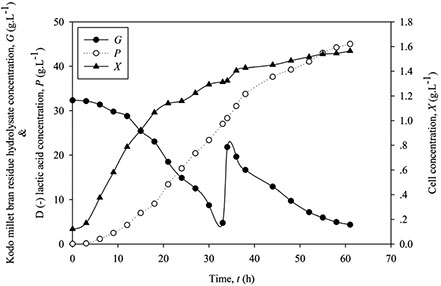

Time profiles of concentrations of cell, KMBRH, and DLA in fed-batch (pulse feeding).

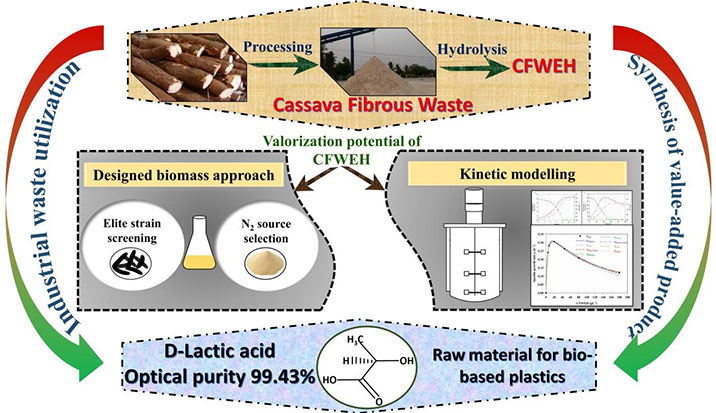

Cassava Fibrous Waste (CFW) is one of the viable feedstock options for DLA production. The processability of CFW and its enzymatic hydrolysis was improved by a novel process intensification attempt of integrating a polymer matrix with enzyme i.e., using a tailor-made electrospun matrix and its application in immobilization of α – amylase enzyme. Fermentation studies were performed using elite Lactic acid bacteria (LAB) possessing feedstock inhibition capability, which was achieved by adopting process intensification step involving designed biomass approach (DBA) and inhibition kinetic modeling. The research outcome offers the knowledge of kinetic parameters, its transformation into operational parameters, which would be helpful for sustainable synthesis of DLA.

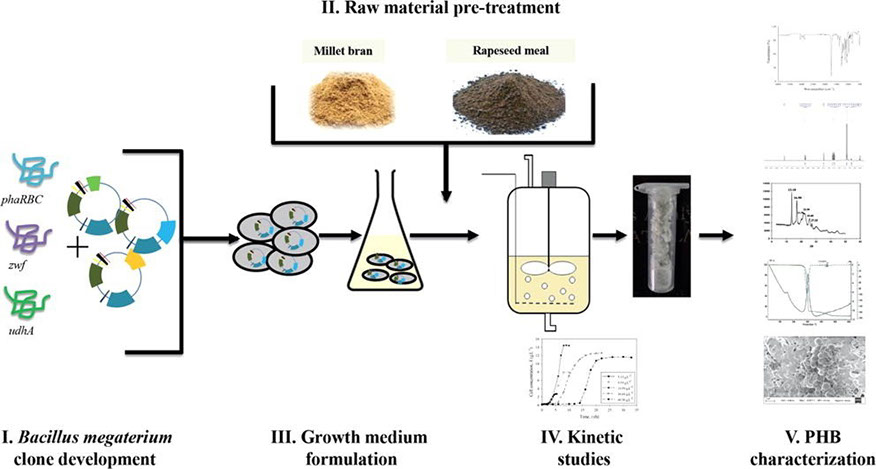

Schematic representation of the PHB production process utilizing millet bran and rapeseed meal hydrolysates. The steps include B. megaterium clone development, growth medium formulation, kinetic studies, and PHB characterization.

Poly-3-hydroxybutyrate (PHB) is a storage compound produced by microbial cells that could be utilized during starvation. Much attention has been attained as it is an attractive alternative to petrochemical plastics, owing to its biodegradability, thermoplasticity, hydrophobicity, and mechanical properties. Moreover, with its inert properties, PHB encompasses wide applications in the biomedical and pharmaceutical sectors.

The microbial platform is under the limelight for PHB synthesis because of its high growth rate and yield. The cost of raw material impedes fermentative (PHB) production at an industrial scale. We successfully tailored B. megaterium to avail waste as a feedstock (millet bran and rapeseed meal hydrolysates) and achieved an efficient PHB titer.

Metabolic engineering of B. megaterium is in progress for enhancing PHB titer, ensuring the feasibility of industrial-scale production. Innovative process engineering approaches and valorization of agro-industrial residues aim to establish a sustainable and cost-effective biopolymer production system.

Schematic representation of the PHB production process utilizing millet bran and rapeseed meal hydrolysates. The steps include B. megaterium clone development, growth medium formulation, kinetic studies, and PHB characterization.

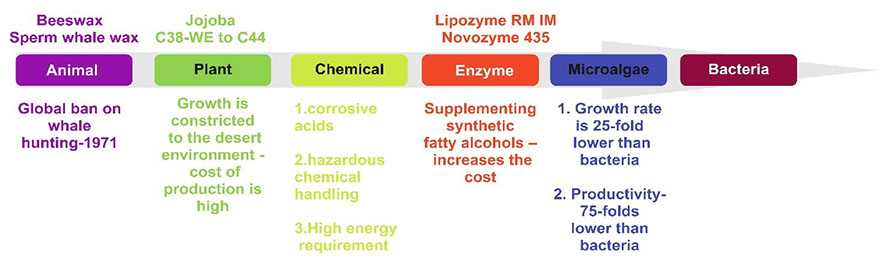

Wax ester (WE) is a high-value neutral lipid formed by the conjugation of fatty acid and fatty alcohol. It has numerous applications such as high-grade lubricants, wound healing, bio-surfactants, gum bases, personal care products, biodiesel production, etc. Depending on the carbon length and the degree of unsaturation, its physical and chemical properties differ, and hence the end application is disparate.

The global ban and high cost of production of animal and plant waxes were the stumbling blocks for its commercialization. Alternate methods such as chemical synthesis and immobilized lipase esterification required the supplementation of precursors. Hence, we have chosen a microbial platform for its production. In silico metabolic engineering of the host organism to identify the genes that would increase the flux towards WE production rather than its competing pathways is in progress. Bioprocess optimization studies are underway utilizing recombinant WE-producing strains to achieve high productivity.

Schematic representation of the PHB production process utilizing millet bran and rapeseed meal hydrolysates. The steps include B. megaterium clone development, growth medium formulation, kinetic studies, and PHB characterization.

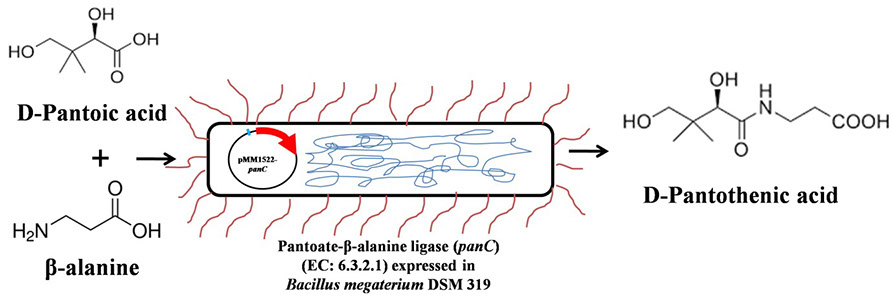

D-Pantothenic acid (DPA) also known as vitamin B5, is a growth factor and an essential metabolite involves in carbohydrate, protein, and fatty acid metabolism. DPA encompasses many applications in the food, cosmetic, and pharmaceutical industries. DPA could be efficiently produced by microbial fermentation using various metabolic engineering approaches. In common, all the existing production routes involve the supplementation of one or both the precursors of DPA. Our group achieved the highest DPA titer of 4.8 g/L without the supplementation of precursors. Currently, the industrial production of these precursors is from petroleum resources. Our group is focussed in developing a microbial system that can synthesize DPA directly from simple sugars without supplementation of both pantoic acid and β – alanine. Implementation of real-time monitoring and control strategies using PAT tools to enhance DPA production is in progress.

Molecular structure of hyaluronic acid.

The complexity in the HA production process has more to be dealt with the process engineering maneuvers than the genetic engineering approaches. Our lab designed different process strategies and successfully utilized PAT tools on monitoring and control of various critical process parameters (CPPs) influencing HA titer and molecular weight. Application of recombinant GRAS organisms as host is in progress to achieve high molecular HA production.

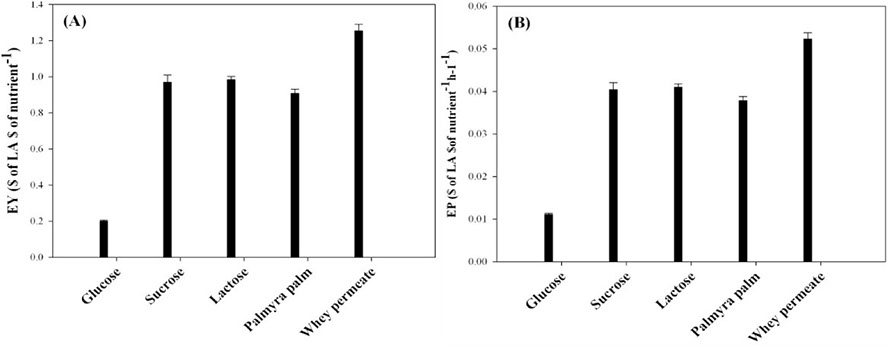

Plantaricin is classified under class I bacteriocins, endows bactericidal activity against pathogenic Listeria monocytogenes and Clostridium difficile. It finds application in food preservation and health care. We are interested in economically efficient production of bacteriocin utilizing low-cost raw feed stocks. In our recent study, whey permeate (WP) based medium found to be economically viable for the production of lactic acid and bacteriocin using L. plantarum CRA52. Further studies in progress targeting metabolic engineering of GRAS organisms for enhanced production of bacteriocin from waste biomass.

Economic yield of lactic acid produced by L. plantarum CRA52 on different carbon substrate-based modified MRS medium.

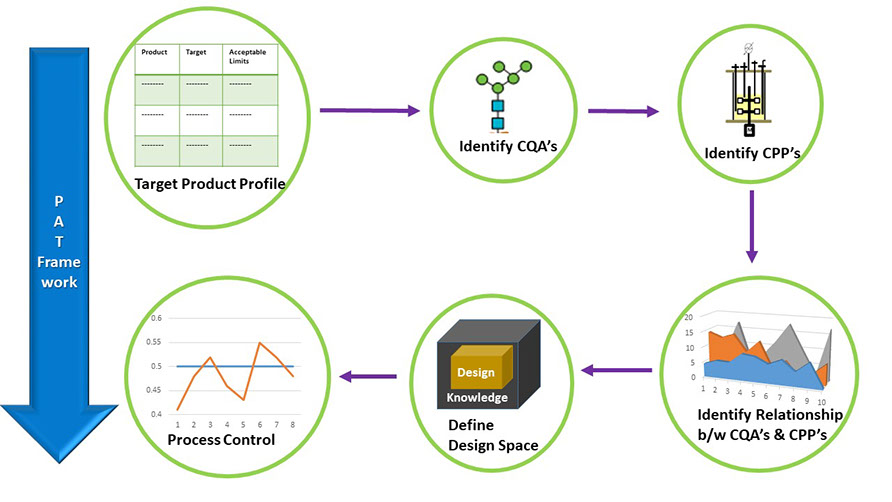

A bioprocess involved in the cultivation of microorganisms undergoes a complex combination of various chemical, physical, and biological changes. As a result, bioprocesses are non-linear and dynamic in nature. In order to produce a quality product at the desired quantity, it is essential for a bioprocess to operate at an optimal environment. Process Analytical Technology (PAT) proposes the conceptual idea of 'Quality by Design' (QbD), emphasizing product quality in real-time at the earliest stage of production rather than quality assessment of the finished product. To implement QbD for a bioprocess, it is important to understand Critical Process Parameters (CPPs) that govern Critical Quality Attributes (CQAs) of a product. Obtaining timely measurements of bioprocess state variables is crucial, and direct information about these variables is seldom available.

Real-time economic yield analysis of lactic acid.

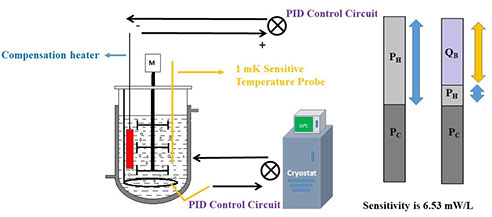

Nearly all microbial systems dissipate Gibb’s free energy because of the thermodynamic spontaneity from the combustion enthalpy of the substrate. Biocalorimeter deciphers biological heat rate, as a result of metabolic interconversions due to the utilization of substrate towards competitive pathways. Heat rate evolved out of the calorimetry offers an advantage to elucidate the viable cell concentration and other kinetic parameters of growth associated.

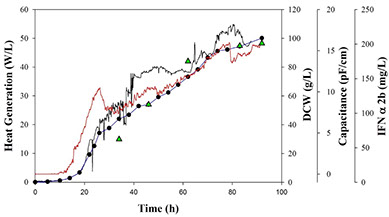

Our research group developed a novel Heat compensation fermentation calorimeter accompanied by two independent PID controls for temperature control during the fermentation process. First, PID control is engaged with the compensation heater in actuating the heater output. Second PID control acts on jacket temperature and two control loops combined to maintain the reactor temperature at the desired setpoint. Successful monitoring of various systems viz., bacteria (Streptococcus zooepidemicus) and yeast (Pichia pastoris) has been accomplished. The calorimetric signals fingerprinted the changes in cellular metabolism and process behavior with viable precision. The developed high-sensitive calorimeter serves as a reliable PAT tool to design a soft sensor to estimate CPP’s like specific growth rate. By employing process control strategies and using information from developed soft sensors, we regulated the substrate feed rate that aided organism growth at the desired specific parameter setpoint value.

Principle of heat compensation calorimeter operation.

Heat Compensation calorimeter as PAT tool for monitoring of hNuPlA2 production using P. pastoris. Real-time heat rate signal (Black continuous) corroborating with real-time capacitance signal (Red continuous) and offline DCW (Blue and Black continuous). (Reference: Srikanth et al., 2020, Biotechnology Progress)

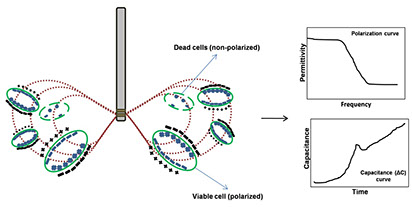

Dielectric spectroscopy (DS) is a process analytical tool employed to measure viable cell concentration in real-time for a fermentation process. It operates on the principle of polarization of cell membranes. Each viable cell carries a charge around the cell membrane, and this charge can be measured in terms of either capacitance or conductance by the probe. As dead cells do not have an intact membrane, they do not act as capacitors. Thus, DS helps in detecting only viable cell concentration.

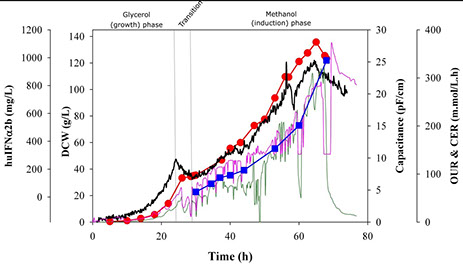

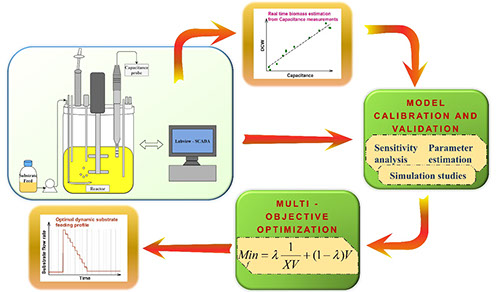

Our group has developed a soft sensor to obtain real-time values of specific growth rate for Pichia pastoris fermentation process. A simple PID-based control strategy was implemented to control specific growth rate in real-time in the production of human interferon α2b. In another study, an optimal substrate feeding profile was achieved by formulating multi-objective optimization (MOO) problem for E. coli systems expressing a recombinant protein. Real-time inputs for mechanistic models deployed to MOO problem were attained through dielectric spectroscopy.

Principle of Dielectric Spectroscopic real-time monitoring of viable cell concentration.

Dynamic profile for dielectric spectroscopy-based monitoring of huIFN α2b production by Pichia pastoris.

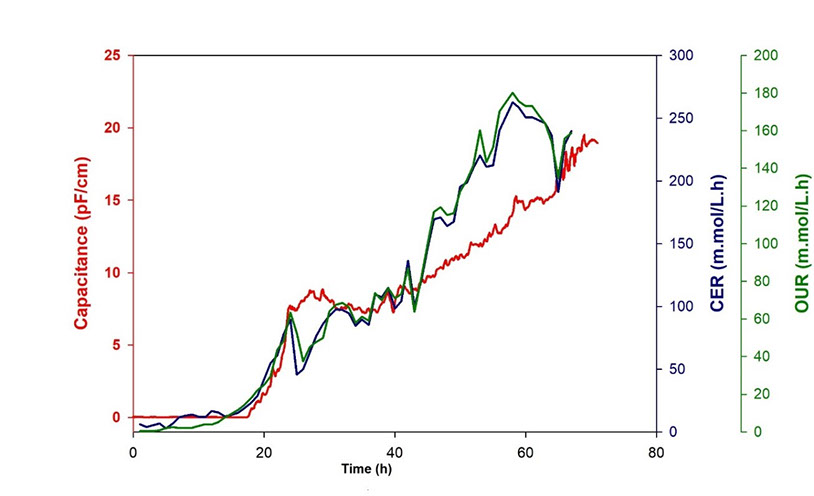

Gaseous phase O₂ and CO₂ concentrations from the exit stream of fermenters are measured in real-time in the form of mole fraction using a lab-scale exhaust gas analyzer. Changes in the concentrations of these exhaust gases could directly fingerprint the ongoing metabolic activities and act as an auxiliary PAT tool for real-time monitoring and control of bioprocesses.

Real-time oxygen uptake rate (OUR) from exhaust gas analyzer (Green continuous) and CER (Blue continuous) corroborating with real-time capacitance signal (Red continuous) for huIFN α2b production by Pichia pastoris (Reference: Srikanth et al., 2020, Biotechnology Progress).

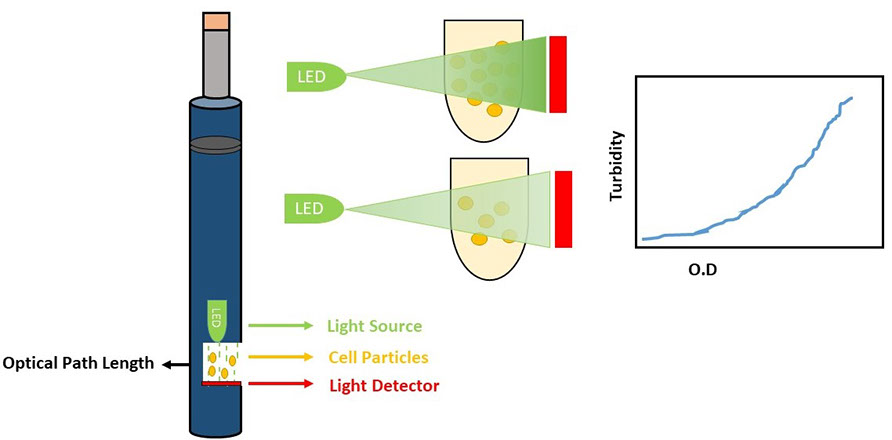

Near-infrared (NIR)-based OD probes can measure the growth of microbial cultures as a function of NIR absorption. NIR light has the advantage of being less absorbed by soluble media components. The attenuation of light intensity caused by absorption by dissolved substances and undissolved material is detected by a hermetically sealed photodiode. This allows for online measurement without sampling or dilution over a vast and linear OD range. A soft sensor can be designed for real-time monitoring and control of bioprocesses by developing correlations with online measured OD values and offline data.

Application of Optical Density (OD) sensor for real-time bioprocess monitoring.

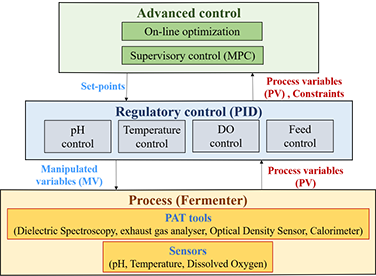

Optimization and advanced process control strategies helps to reduce process variations, thereby aiding in maintaining the quality of the desired product. Since product quality is a critical quality attribute (CQA) in bioprocesses, suitable control schemes to maintain it are crucial for Process Analytical Technology (PAT) implementation. The dynamic and nonlinear nature of bioprocesses emphasizes supervised control strategies to handle these challenges.

Strategies like Model Predictive Control (MPC) manage multi-input multi-output (MIMO) systems effectively. Additionally, their predictive nature allows for real-time corrective actions to minimize batch-to-batch variations. Objectives like maximizing process yield, product concentration, and minimizing by-product formation can be achieved through advanced strategies.

Overview of advanced process control strategies in bioprocesses.

Multi-objective optimization (MOO) for achieving optimal substrate feeding profile (Reference: Swaminathan et al., 2020, iGEC).

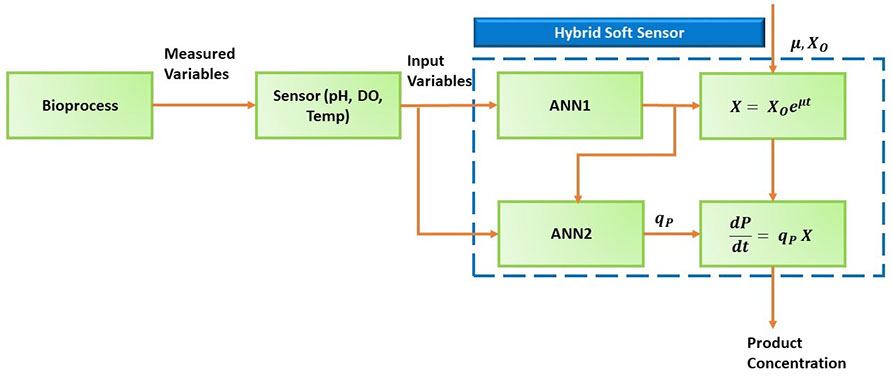

Soft sensors, or software sensors, have been used in industrial process monitoring for the last 1–2 decades. They provide real-time estimation of state variables that are otherwise difficult to measure or only measured infrequently. A hybrid model combines mechanistic and data-driven approaches to predict state variables, which are then used as inputs for mechanistic models.

This method minimizes the need for extensive data while offering advantages over purely data-driven methods. Our group developed a hybrid-based soft sensor by combining data-driven and mechanistic models to predict hyaluronic acid concentration in bioprocesses.

Application of hybrid soft sensor for bioprocess monitoring.

| S.No | Title | Cost (in Lakhs) | Duration | Role as PI/Co-PI | Agency | Status |

|---|---|---|---|---|---|---|

| 1 | Metabolic Reprogramming of Kluyveromyces lactis and Advanced Bioprocess Development for the Bioproduction of Low Molecular Weight Heparin to Treat Blood Clotting Disorders | 115.99 | 3 Years | PI | ICMR | On-going |

| 2 | Repurposing Industrial Sweet Potato Wastes to Bacterial Cellulose With Applications in Food and Biomedical Sectors | 62.80 | 2 Years | PI | NFTPL Industry | On-going |

| 3 | Metabolic engineering of Rhodococcus opacus: A potential workhorse for lignin valorization into high-value lipids | 58.96 | 3 Years | PI | SERB-SUPRA | On-going |

| S.No | Title | Cost (in Lakhs) | Duration | Role as PI/Co-PI | Agency | Status |

|---|---|---|---|---|---|---|

| 1 | Process Analytical Technology (PAT) control tools for high cell density cultivation of glyco-engineered Pichia pastoris for Human Interferon Alpha2b production | 43.00 | 3 Years | PI | SERB | Completed |

| 2 | Parallel Bioreactor facility, located at BSBE Dept, IITG | 150 | 5 Years | Co-PI | DST-FIST | Completed |

| 3 | Development of optimal bioprocess strategy for production of D-Lactic acid from cassava waste by amylolytic lactic acid bacteria | 11.00 | 3 Years | PI | CSIR | Completed |

| 4 | Continuous processing for production of biotech therapeutics | 1089.27 | 5 Years | Co-PI | MHRD | Completed |

| 5 | Design and Application of a Robust Process Analytical Technology (PAT) Platform for Real-time Monitoring and Control of Hyaluronic Acid Production | 78.348 | 3 years | PI | DBT | Completed |

| 6 | Application of Dielectric Spectroscopic Measurements for Real-time Monitoring and Control of High Cell Density Cultivation (HCDC) of Pichia pastoris for Production of Glycosylated Human Interferon Alpha2b | 20.57 | 3 years | PI | DST | Completed |

| 7 | Continuous fermentative production of D (-) lactic acid using whey as feedstock in automated membrane integrated bioreactor | 44.64 | 3 years | PI | DBT | Completed |

| 8 | Metabolic engineering of Bacillus megaterium for enhanced production D (-) pantothenic acid and its application for the development of functional foods | 36.73 | 3 years | PI | DBT | Completed |